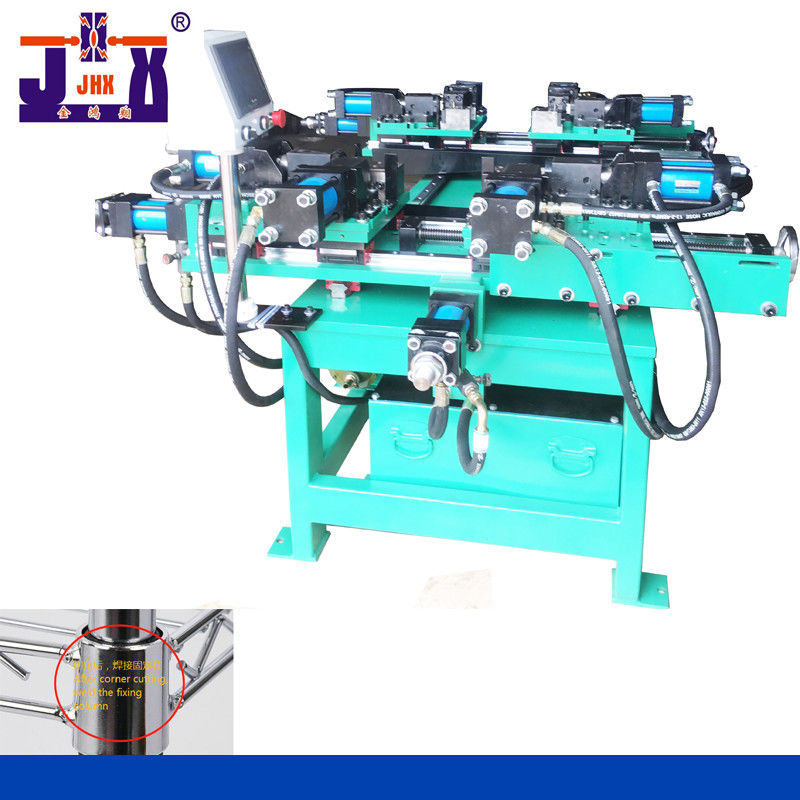

Corner Cutting Machine 8 iron wires can be cut at the same time

Name:

JWPQJ 1848 corner cutting machine,

mesh corner cutting machine,

shelf mesh corner cutting machine,

shelf special machine,

4818 mesh special machine

Function

It is used to cut the corners of the four corners of the mesh of the shelf, cut the required space at one time, and it is convenient to weld the column sleeve of the shelf. The product corner cutting is neat and standardized, which is more convenient for robot automatic welding in the later stage.

Performance characteristics

1. Input voltage 380V, 50Hz, Hydraulic motor power 7.5kw + special high-pressure pump. Large force and fast oil pump make multiple oil cylinders work harmoniously and react quickly.

2. There are 11 heavy-duty oil cylinders 4 + 4 + 3 in total. The oil circuits are precisely arranged, coordinated and fast. There are 8 cut-off cylinders. One cylinder cuts 2 lines and four corners. 8 lines can be cut at a time, which is fast. Cutting a mesh takes only 1-2 seconds.

3. PLC programming + man-machine interface display, simple setting, convenient adjustment and change.

4. Specification of cutting mesh: 1848 inches. Range can be adjusted before and after.

5. For the incision, the standard state is that the incision is perpendicular to the mesh, and other angles can be made as needed.

Detail display

1. In the front and rear direction, the large load-bearing slide rail + screw rod, and the worktable

can move back and forth to facilitate the corner cutting of mesh with different widths.

2. Left and right direction, large load-bearing slide rail + screw rod, the worktable can be moved left and right,

which is convenient for mesh corner cutting of different lengths

3. Large cold water pump ensures that multiple oil cylinders can work quickly without heating.

4. PLC programming + man-machine interface, simple and convenient operation.

Product display

Technical parameter

| technical parameter |

| Model |

Input voltage |

Hydraulic motor |

Maximum mesh size |

Minimum mesh size |

Overall dimension |

Weight |

| JWPQJ1848 |

380V50HZ |

7.5KW |

18*48 inches |

13.5*13.5inches |

2.5M*1.5M*1.2M |

1100KG |

Pack and export to Vietnam

Our service:

The Company have been specializing in the production of welding forming equipment for more than 20 years,

with strong technology, sophisticated experience, leading product quality in the industry,

and have a good reputation in the industry. Each equipment is equipped with spare parts of excellent quality.

Each equipment has undergone strict ex factory aging commissioning and long-term work trial. Besides,

there are professional after-sales service technicians who can provide video guidance on installation

and debugging at any time during working hours.

"All equipment shall be guaranteed for one year and maintained for life.

You buy with peace of mind, using is very satisfactory!!

Our purpose:

every equipment should be the best!!

Warm tip:

our products are constantly upgraded and improved.

If the color or structure changes, the real object shall prevail.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!